235 Strathearn Avenue

Richmond Hill, ON L4B3C4

ph: (905) 780 6515

fax: (905) 770 3254

service

Turn-Key Project

TOTAL SOLUTION FOR

UPVC Windows & Doors.

In recent years Canadian Industrial Technologies Inc. in cooperation with major Canadian & European Plastics Industry erected several plants for production of windows & doors from UPVC ( Unpalletize Polyvinyl Chloride) in countries all around the globe .

Our organization - from the sales management to the technical department - is specifically set up to deal with complexity. Our skills in analyzing problems, proposing solutions, and making decisions are consistently applied beginning with the first contact we make with the customer, and extending to our service after the Quality derives from a combination of contributing factors which include experience gained over the years and continuity offered to new ideas.

Major standard machineries for Mixing Plant , Extrusion Line , Down Stream Line , Lamination Line , Fabrication Line and Glazing Line will be supplied from stat of arts world leading suppliers . Together with these highly experienced people from Canexa Chemical Inc. & Plastek Inc. (Canada ) Ariostea & Plasmec ( Italy ), Cincinati , Gruber Group, Lisec ( Austria ) , Wegoma (Germany ) and Pertici ( Italy) our young and powerful company could enter the market of project business where complete extrusion factories where engineered and erected in countries all around the globe .

These companies with engineering , planning and coordination of our leading team work together to supply some of the World’s most Innovative Solutions for PVC Profile and Wood-plastic Extrusions.

Our Company is the contact for our customers all over the world. It sells complete turn key solutions. Some of the most experienced people in the whole industry with more than 25 years experience are member of our team. They bring all the necessary know how together to establish a perfectly working turn key solution to our clients.

The rapid growth of our company in the last years proves that we are obviously doing things right. We could win many regular customers due to our excellent products and services.

We are looking forward to talking to You about Your future PVC or Wood-plastic Extrusion Project.

Our main partners in turn key solution:

Canexa Chemical Inc. :

The company established in 1993 and in cooperation with Shell Canada & DuPont provides whole range of chemical and petrochemical raw materials and know how on formulation on compounding for different application in plastic industry .

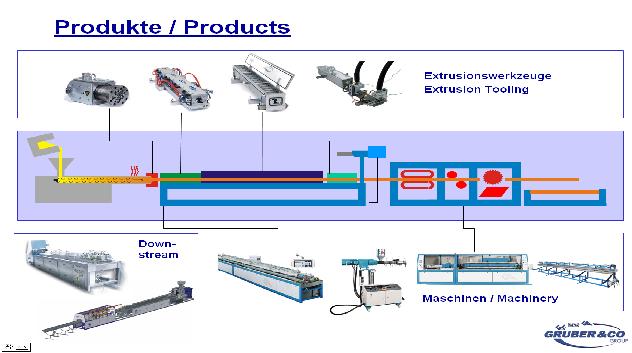

Gruber & Co.Group

The GRUBER & CO Extrusionstechnik company is our factory for extrusion tooling. This is where from the sophisticated design work to the highly skilled final tuning the finest know-how of extrusion is concentrated. a+g extrusion technology is responsible for our highly innovative extrusion downstream which has become a world famous brand in the established European and North American markets as well as in the now rapidly growing markets of Eastern Europe, Near and Middle East and Asia. Some of the other companies are supplying our leading edges with parts manufacturing or marketing and IT-Services.

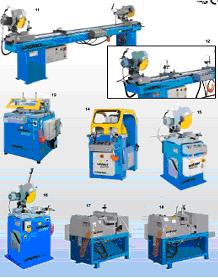

Pertici S.p.A. is a leading manufacturer of machines for the door/window industry, and in almost any other industrial activity which involves the machining of aluminum, PVC or similar materials. Founded in 1967, the Company started off with the production of traditional wood-working machines and subsequently developed the production of machinery for the aluminum and PVC door/window industry, with OEM agreements with some of the major German machinery manufacturers. Today they have achieved a consolidated Customer's base thanks to the quality and reliability of their products, a direct consequence of the high production standards. The strongest point, recognized by all Customers are today the top quality of our after-sales services and the very short deliveries that, together with the machines, reliability, are the values of Pertici S.p.A.

The company was founded in 1950 and worked as a major supplier of systems for the industrial handling of powders and granules.

An Ariostea handling system is the intelligent answer to the increasing demands of modern production processes. Highest possible quality and also highly innovative solutions for making compounding more efficient the company started a rapid growth with customers mainly coming from Western Europe & North America ( United State , Canada England, Germany, Austria, France). We produce

Dedicated Solutions:

The handling of powder or granule materials has assumed central importance in many industrial contexts. We offer each customer a dedicated solution, capable of satisfying the specific requirements of his particular production sector. Ease of maintenance and after-sales service are integral parts of our global approach. Ariostea builds systems for:

- Producers of PP, PS and PE film and sheets

- Producers of extruded profiles in PVC

- Producers of PVC film and sheets

- Injection molding and roto-molding plants

- Recycling plants for PE, PET and PVC

- Processes of various nature verified by our technicians and tested in our testing laboratory.

Plants for PVC extruded profiles production are essentially composed by main stocking area where PVC and calcium carbonate are stocked in silos with fitted accessories to avoid dust outlet and to make material discharge with more problems easier.

Material is batched in the conveying line through fitted extractors, screw feeders, star valves, to be flight weighted in the main scale located directly on the turbo-mixer, where also the components of the additives area arrive from sacs and big-bags weighted in appropriated scales with very high precision.

After main market leader for many years. The modern mixing technology would not be existing without the innovations that came from this company.

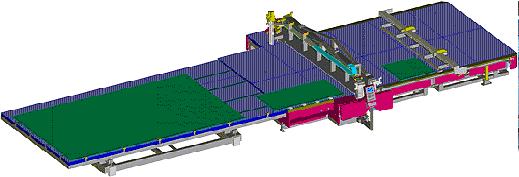

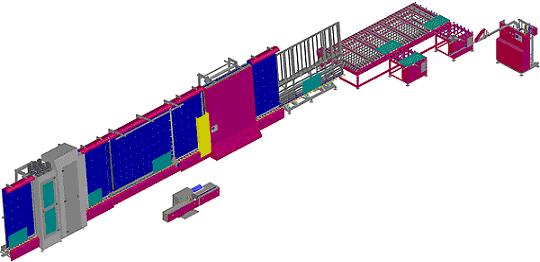

LISEC Austria

Originally a glass processing business establishment, Lisec has expanded over a period of decades into the world´s largest manufacturer of high-tech production lines for the insulating glass industry.

40 years of Lisec´s experience in the field of flat glass, engineering and insulating glass production together with intensive research and development, as well as a global consulting and service network stand for High Tech, Know How and Quality Made in Austria.

On October 20 in 1961 the company was founded by Mr. Peter Lisec as one man business. Even at that early stage own ideas were realized although the production range was quite small. The main performances were the bending and forming of acrylic glass, mirror manufacturing and glass edging.

1978 the Company has grown-up to 150 employees, who, beside of the insulating glass department, developed and produced considerable numbers of machines and plants for automated i.g. manufacturing using the experience from the own glass shop. A hard battle for shares of the market in the machinery field against old-established foreign competitors required some extensive investments. A second production facility was built to enable the spread-out of the machine department to approx. 20.000 sqm. Since then the machine production dominates; just about 10 % of the total turnover is contributed by the glass processing.

2006 sees another enlargement of the Seitenstetten plant by 7000 m2 after building the new assembling hall 4 and extending the common and office rooms. This creation of new production areas requires also a large scale investment in the latest manufacturing equipment to meet the worldwide exploding demand for the Lisec quality products. A lot of of new employees are educated to become qualified specialists - so the Lisec Maschinenbau GmbH employs more than 600 persons. Worldwide the Lisec staff exceeds 1600 people.

2007 Lisec receives the Austrian Innovation Award for its revolutionary "flat-bed" glass tempering technology. This patented innovative glass tempering technique was developed by the Lisec research and development center in Seitenstetten for which the company provides every year approx. 8 % of its turnover and which puts Lisec in the position of the technology leader in the field.

235 Strathearn Avenue

Richmond Hill, ON L4B3C4

ph: (905) 780 6515

fax: (905) 770 3254

service